Technical challenges

- To find a solution for robust positioning and navigation of the pool cleaner under water without the need of installation of additional equipment in the pool.

- To find a mechanical and electronic design that supports the requirement of modularity without adding cost and complexity.

- To achieve cost target whilst maintaining or improving cleaning performance.

Integrated solution

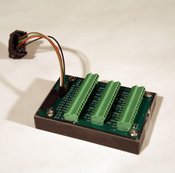

The electric control unit is located in the robot which is underwater, therefore requiring it to be completely encapsulated in order to stay water tight. To achieve the high requirements of housing the electronics, the number of cables connected needed to be minimized by having almost all sensors integrated directly on the printed circuit board. This has been possible by replacing the traditional positioning sensor with new types of sensors combined with advanced signal processing.

Robotic Pool Cleaner

A pool cleaner cleans a pool floor of litter, sediment and dirt. As an example, an average swimmer leaves 4 grams of organic particulate every time they go for a swim. The company WEDA Pool Cleaner manufactures and sells professional pool cleaners on the global export market. Their current product range of pool cleaners have looked roughly the same ever since the early 1980’s. The design by WEDA was essentially a mechanical solution and has not changed to any great extent since the first model was sold. However, the design is known for its excellent quality, reliability and long service life. But, the design of modern pools and bathing establishments has changed from the traditional rectangular shape to more irregular shapes. In addition, the new pools have not only increased in size but also now may have additional features such as beaches, canals, islands and waterfalls. In brief, this makes today's mechanical solution outdated and unable to successfully clean these new complex and large pools in a satisfactory way.

Technology description

Intelligent Machines has conducted a comprehensive feasibility study - including verifying experiments, to find technical solutions for a new generation of pool cleaners with a more autonomous behavior and significantly lower production cost. The study led to an experimental prototype being built to verify the technical concept. The feasibility study began with defining the specification of requirements which included both market and technical requirements. The feasibility study examined nine different methods for positioning and navigation with two of them being selected for further work. Both of the methods chosen were based on the time of flight of ultrasound. To use ultrasound in pools with surrounding walls created a series of problems that were required to be solved in order to achieve good positioning. The long reverberation time and multipath of the ultrasonic pulses were some of the issues dealt with in the technical solution. A completely new mechanical design was developed to enable a modular product which could be built cost-effectively in different versions or models. Suggestions were made on how the sensors, electronics, software and mechanics must be integrated with each other to obtain higher reliability and lower cost.

Gyro

The positioning and navigation system includes a solid state gyroscope to better follow the calculated trajectory. Intelligent Machines has also developed a positioning system for pool cleaners solely using the gyroscope. This system allows the robot to follow calculated paths with just the right amount of overlap while maintaining high class and fast cleaning. This is done even with external influences such as the pool bottom, floating cables or flowing water in the way. The electronics are encapsulated to withstand humid environments and resist rough handling during assembly.

Fact box

- IM has put together market demands and transformed these into a specification of requirements.

- IM has made a technical feasibility study to identify new technology solutions that meet the specification of requirements.

- IM has built experimental prototypes and conducted experiments in full scale to verify the technology solutions.

- IM has been in charge of the entire research project by developing system solutions, software, hardware and mechanics to the first prototype.